Hydro-Platers offers both mid phosphorus and high phosphorus electroless nickel plating. electroless nickel is often used on various types of parts to protect against wear and corrosion. The uniform deposit of nickel is especially useful for hydraulic cylinders, worm feeds, gears, bellows, shafts, chain belts and other close fitting components. There are also many other uses of electroless nickel where the coating can provide reduced cost, longer life and improved reliability. These included domestic appliances, plumbing fixtures, and food processing equipment, sanitary ware, photographic processing equipment and solar absorber surfaces.

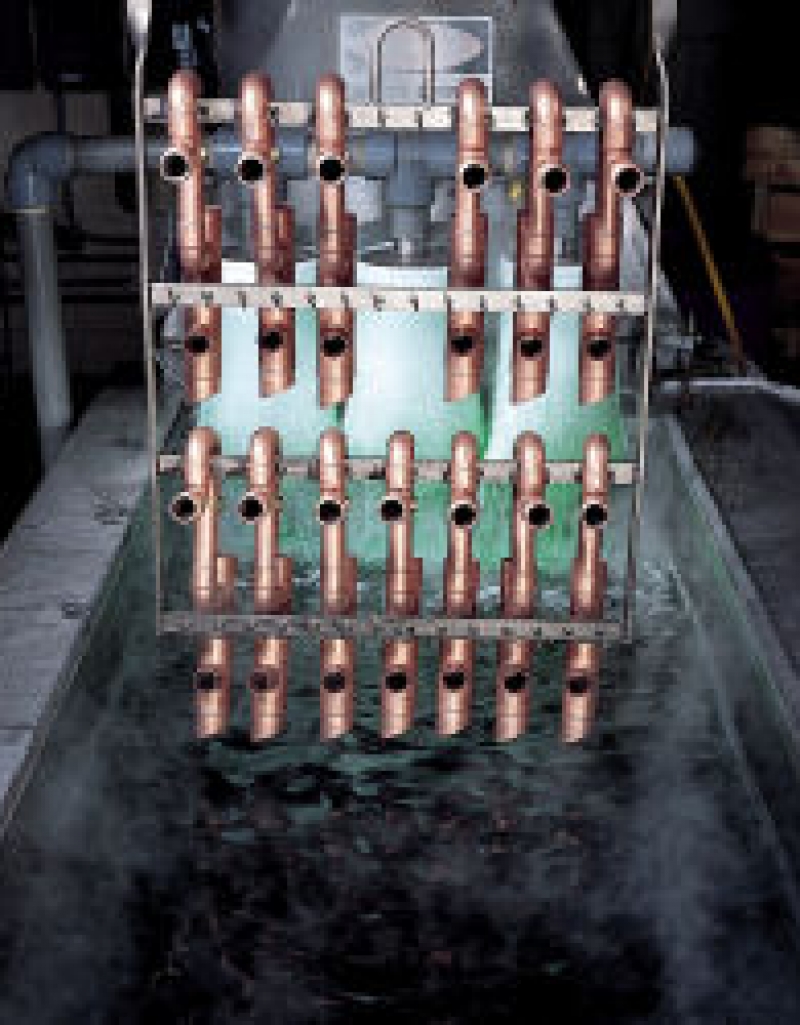

ELECTROLESS NICKEL PLATING

MID PHOSPHORUS ELECTROLESS NICKEL CONTENT

- 7 to 9% (depends on age of Electroless Nickel bath and operating pH)

HIGH PHOSPHORUS ELECTROLESS NICKEL CONTENT

- 9 to 12% (depends on age of bath and operating pH)

HARDNESS OF PLATING

- As plated, 500 to 600 D.P.H. (48 to 50Rc)

- Heat treated to 400ûC (750ûF) for 60 minutes. 900-1000 D.P.H. (60 to 70) Rc)

DUCTILITY OF PLATING

- Will pass 180û bend test as specified by MII-C-26074 and ASTM B 571

COLOR OF PLATING

- Semi-bright Electroless Nickel deposit resembling polished stainless steel

MAXIMUM CAPACITIES: WIDTH 30 Inches LENGTH 78 Inches DEPTH 60 Inches WEIGHT 2000 Pounds

EXISTING FACILITIES TO ALLOW FOR THE SET UP OF ADDITIONAL TANKS • To accommodate an increase in our customer base and work load